INTRODUCING OUR MIXER

Enhanced performance, repeatability and the ability to clean and sterilize-

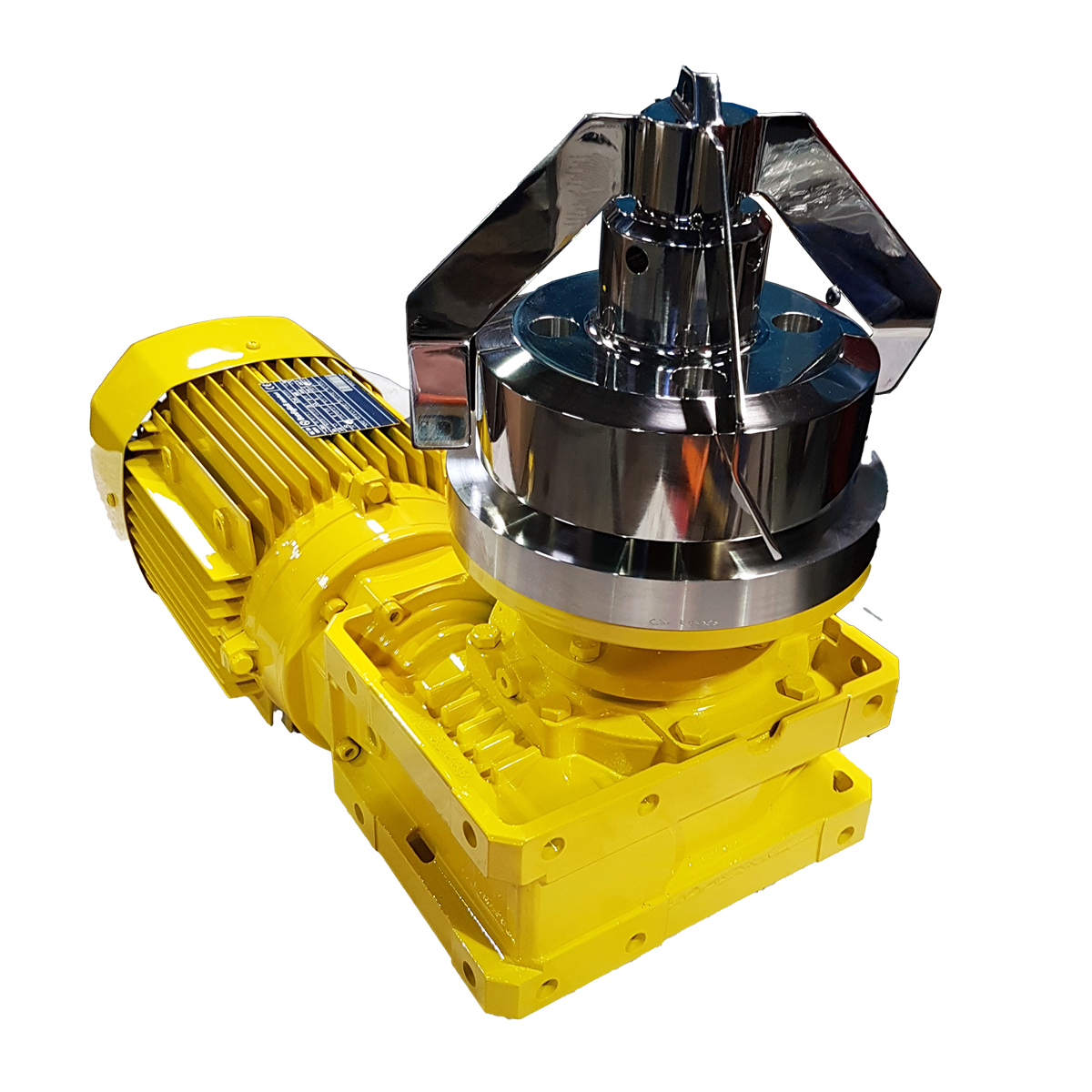

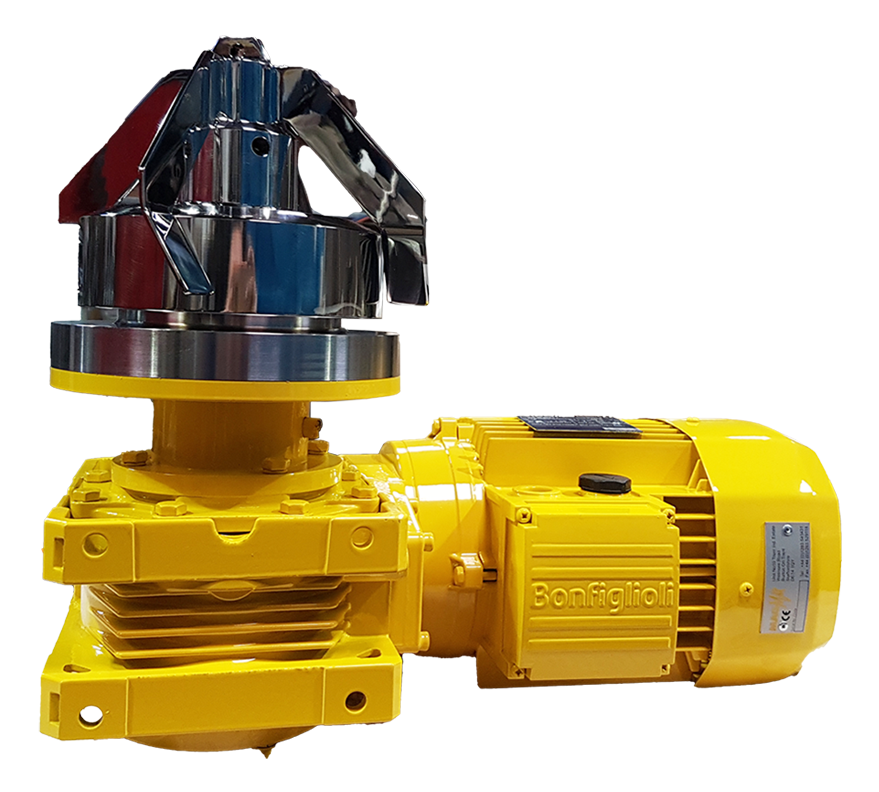

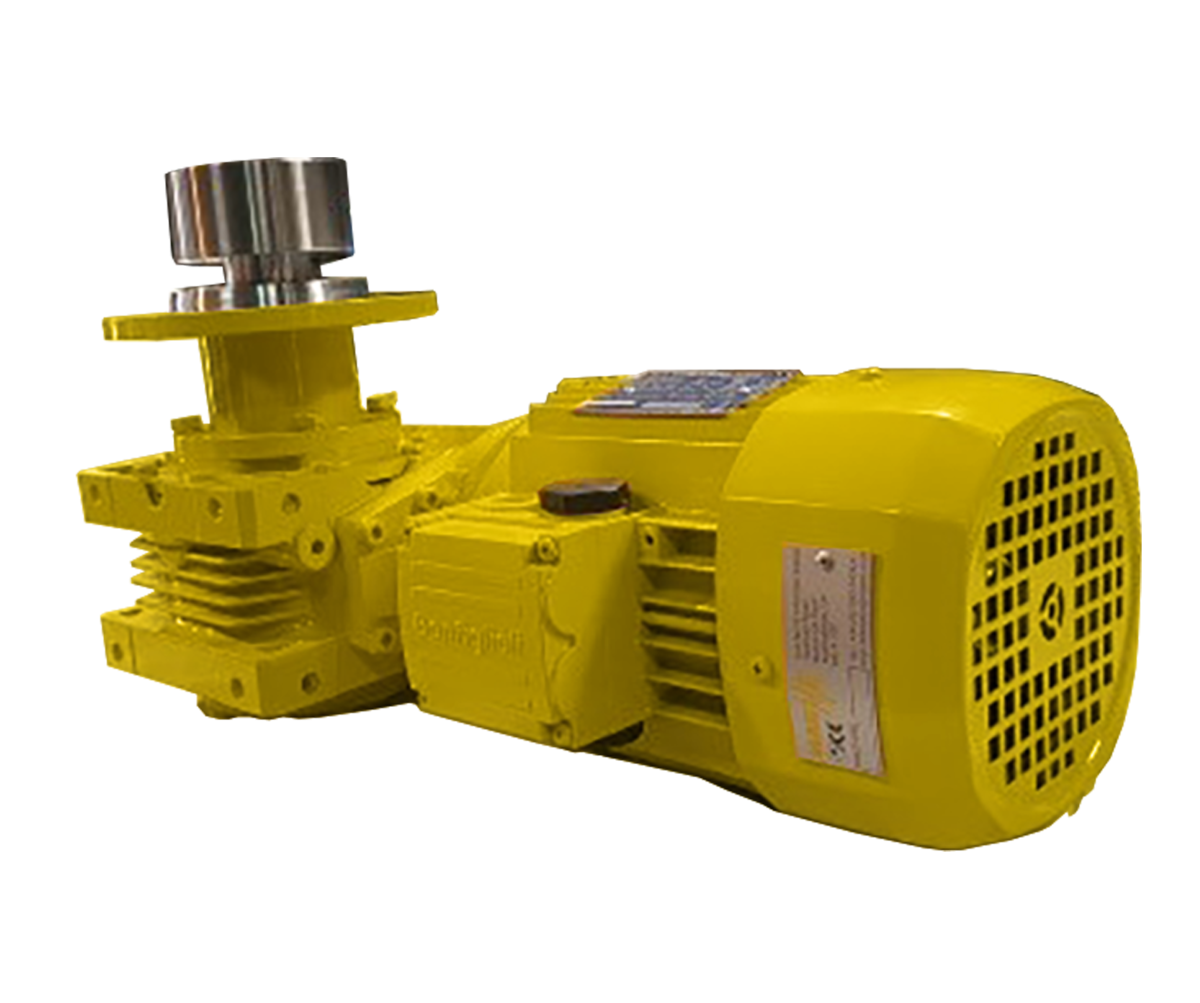

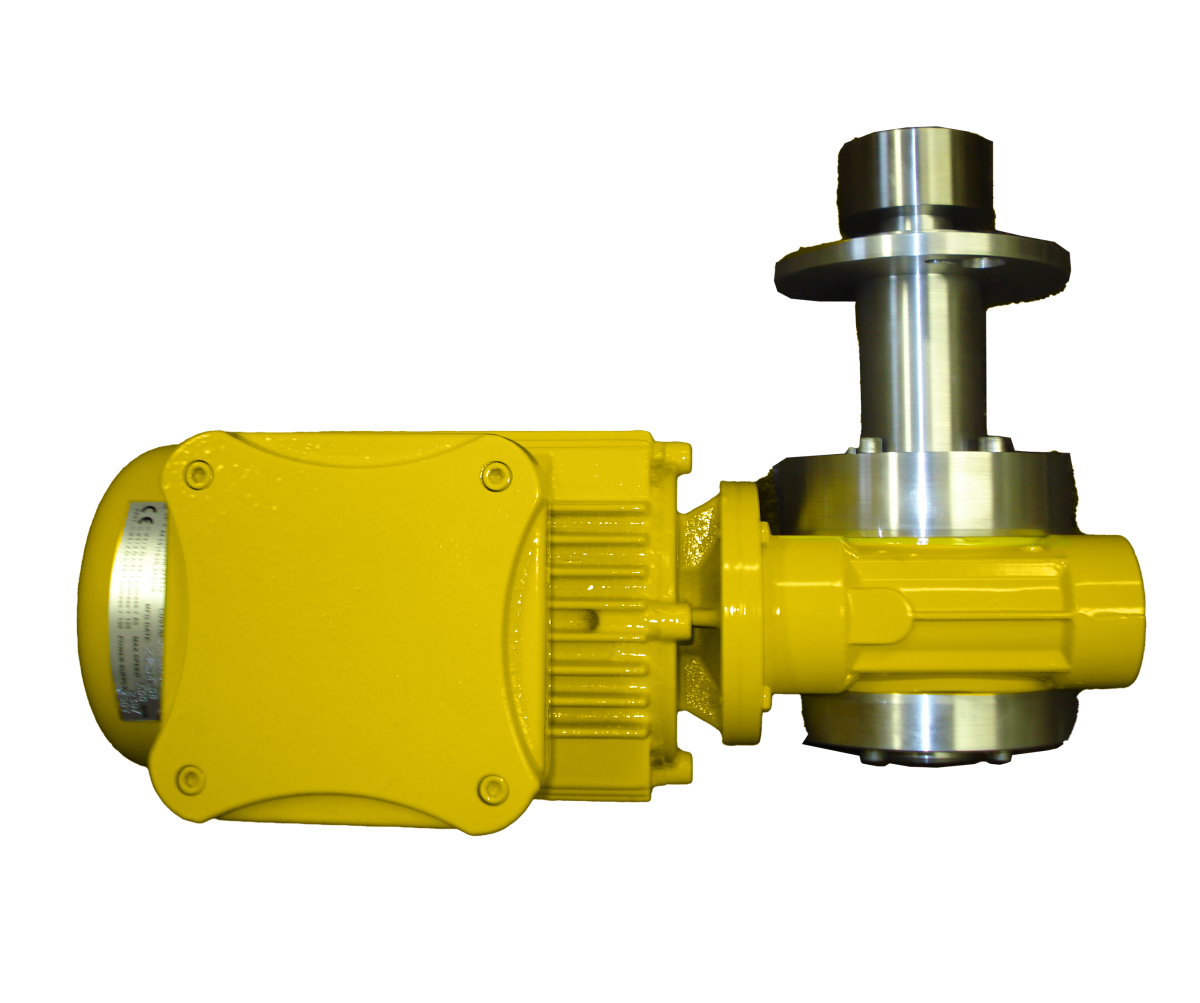

The MagMix Mixer offers the complete mixing solution for use throughout your process with its advanced mixer. Offering durability and easy maintenance while providing you with superior mixing performance and mixing efficiency.

MagMix is mounted on a custom designed bearing and vessel pad which can be welded into the base of virtually any process vessel and tank integrity is maintained as no shaft is led through the vessel wall

WHY MAGMIX?

Magmix gives our key areas the Pharma and Food & Beverage producers peace of mind.

Our high precision bottom entry mixers are built for excellence, longevity and very easy low maintenance. Our Mixer is built in house at our UK based site and is distributed by us and our agents to serve the many sectors we serve with our Mixer worldwide.

Why Our Mixer ?

The Mixer is a proven mixer out in the field which we have supplied to many Blue chip Clients worldwide and still continue to do so as it is a tried and tested mixer also.

The Mixer can be cleaned and sterilsed in place

No mechanical seals to eliminate the risk of contamination

Our Drive units can be transferable with a quick release clamping system so the mixer can be transferred to several vessels providing cost effective mixing in several vessels

Complies with all pharmaceutical, healthcare and food regulations

Very minimum low maintenance required with the mixer once installed

Can mix very low volume medias from as little as 10 Litres up to 30,000 Litres

Can be run with a standalone Control Panel for Variable Speed Control or can be integrated into an existing PLC

Spare parts are always in stock for us to be able to ship to our clients Next Day so minimum downtime should spares be required speedily to reduce this.

Mixer can be retro fitted to most vessels containing an existing weld plate from another make

quality

Our Magmix Magnetic Mixer is fully built and certified through our own ISO9001:2015 certification and we can also offer the Mixer for full ATEX Compliance.

Among the available certifications and various declarations of conformity we can offer to name a few are listed below :

- Materials in contact with the product according to EN 10204 3.1,

- FDA 21 CFR 177.1550,

- USP Class VI 121 ͦ,

- TSE EMA/410/01 rev.3

- Conformity of the surface finish,

- ATEX certification according to the European Directive 2014/34/EU

Sales &

After Sales

Magmix Offers a commitment to quality and customer satisfaction not only upto the sale but also long after the mixer has gone into service by offering continued support and advice and also readily available spares at affordable prices as and when required

THE MAGMIX MIXER RANGE

DC MIXER

For Mixing Capacity of 10 Litres up to 150 Litres , This Mixer is used generally for R&D purposes and Small Batch Processing.

AC MIXER

For Mixing Capacity of 10 Litres up to 30,000 Litres. Our Standard Mixer is Used in nearly all standard environments

AIR MIXER

For Mixing Capacity of 10 litres up to 3000 Litres. It can be used if no Electricity supply is available or Sterile Environments

ATEX MIXER

For Mixing Capacity of 10 Litres up to 30,000 Litres. Used in Explosive or Fire Risk Environments. Available in both AC and Air Drive Unit Options.

Interchangeable Mixing Heads

From Stock –

We can design and manufacture mixing heads to meet specific requirements.

The stainless steel (AISI 316L) heads are hygienic with minimal contact surfaces, which are crevice free. They are compatible with pharmaceutical, healthcare and food requirements. Simplicity of design assures maintenance free operation. The mixing head bearing is lubricated by process fluid, During operation, magnetic flux between permanent magnets acts to levitate the bearing surfaces and thus minimises bearing wear.

Transferable Drive Unit

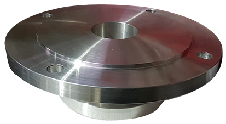

The external drive unit of Magmix is attached to the process vessel using:

a: Bolted Flange ( MM20, MM32, MM64 )

b: Bayonet Clamp ( MM8, MM12 )

c: Tri Clover Clamp ( MM4, MM6 )

Control Panels

Fully Bespoke Built Panel to Suit the Customers Specification

Fully Built to Current Electrical and Wiring Regulations

Can Be Supplied for IP55 , IP65 or ATEX Environments

Full Variable Speed Control of the Mixer with speed readouts

Models MM4, MM6, MM8, MM12, MM20 require single-phase supply, MM32 and MM64 require three phase supply

AIR CONTROL

Fully Bespoke Built Panel to Suit the customers Specification

Fully variable speed control of the mixer from the panel

Can Be Supplied for IP55 , IP65 or ATEX Environments

Speeds of 100 upto450 rpm using 6 bar lubricated air

Suitable for MM4,MM6,MM8,MM12 & MM20 Models

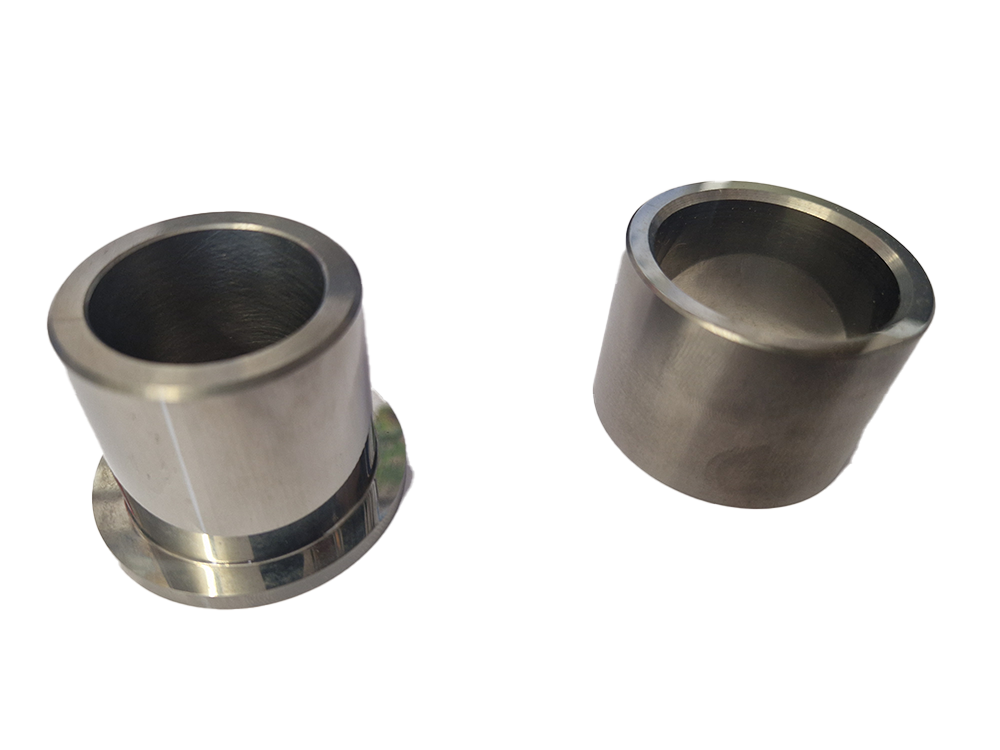

BEARINGS

MagMix bearings consists of a pair of special grade tungsten carbide mirror finished plain bearings. The static bearing is fitted to the vessel pad with a special aseptically designed retaining nut. For more aggressive medias a Silicon Carbide or Zirconium Bearings can be offered as an alternative.

Where vessels are hard to access for regular maintenance we can offer a fixed mixer pad bearing which reduces maintenance schedules allowing more process time and less down time.

Adapter Kits

An adaptor kit for the MagMix Mixer enables it to be fully interchangeable with some of the other magnetic mixers of similar size, currently on the market. The kit can be used in three ways:

- To drive impellers of another make

- Drive units of another make, which can drive one of the MagMix Mixing heads

- MagMix can be retrofitted to most vessels containing a weld plate of another make, negating the need to modify the vessel.

MAGMIX MIXER CAPACITIES

| Model | Vigorous Mixing Upto | Gentle Mixing |

|---|---|---|

| MM4 | 10 Litres | 30 Litres |

| MM6 | 50 Litres | 10 Litres |

| MM8 | 150 Litres | 500 Litres |

| MM12 | 300 Litres | 2000 Litres |

| MM20 | 1000 Litres | 3000 Litres |

| MM32 | 2000 Litres | 6000 Litres |

| MM64 | 3000 Litres | 30,000 Litres |

JUST SOME OF THE BENEFITS OF THE MIXER.

No Mechanical Seal

The Magmix has its own bespoke welded in vessel pad , eliminating the need for complicated mechanical seals which are liable to leak and can lead to product contamination and other risks.

Transferable drive unit

If you have more than one of the same vessel and Mixer the Driveunits can be transferable to each vessel so can save on costs and also as the external drive unit is attached to the mixing vessel pad with a quick release tri-clamp or slide up clamp system to allow a quick changeover with minimum downtime.

MagMix can be supplied with a control unit

The Mixer can be supplied with a Stand alone control unit if required, which in turn gives a stepless variable speed facility, ensuring full control of mixing power during start-up, product blending and vessel draining with many options to suit our customers needs these are truly built to the customers required specification.

MagMix is a bottom drive design

Our MagMix Mixer is a pure bottom drive design which when fitted with a low volume mixing head, very low controlled blending can be achieved and all Internal surfaces can be cleaned and sterilised in place (CIP, SIP) using pressurised steam and without the need to remove any parts from the vessel.

Fully ATEX Compliant mixer

Fully ATEX Compliant Mixers and control Panels can be supplied as an option.

Mixer Compliance

Complies with all pharmaceutical, healthcare and food regulations.