Simple, hygienic design

Simple, hygienic design. The compact mixing head is the only moving part inside the mixing vessel, offering reliable and virtually maintenance-free operation.

THE MAGMIX RANGE

The MagMix range can be offered in AC, DC , Air and Atex Drive Units and can mix media from 10 Litres upto 30,000 Litres

FOR APPLICATIONS IN PHARMACEUTICAL, FOOD, BIOTECHNOLOGY, COSMETICS & CHEMICAL.

THE MAGMIX MIXER RANGE

DC MIXER

For Mixing Capacity of 10 Litres up to 150 Litres , This Mixer is used generally for R&D purposes and Small Batch Processing.

AC MIXER

For Mixing Capacity of 10 Litres up to 30,000 Litres. Our Standard Mixer is Used in nearly all standard environments

AIR MIXER

For Mixing Capacity of 10 litres up to 3000 Litres. It can be used if no Electricity supply is available or Sterile Environments

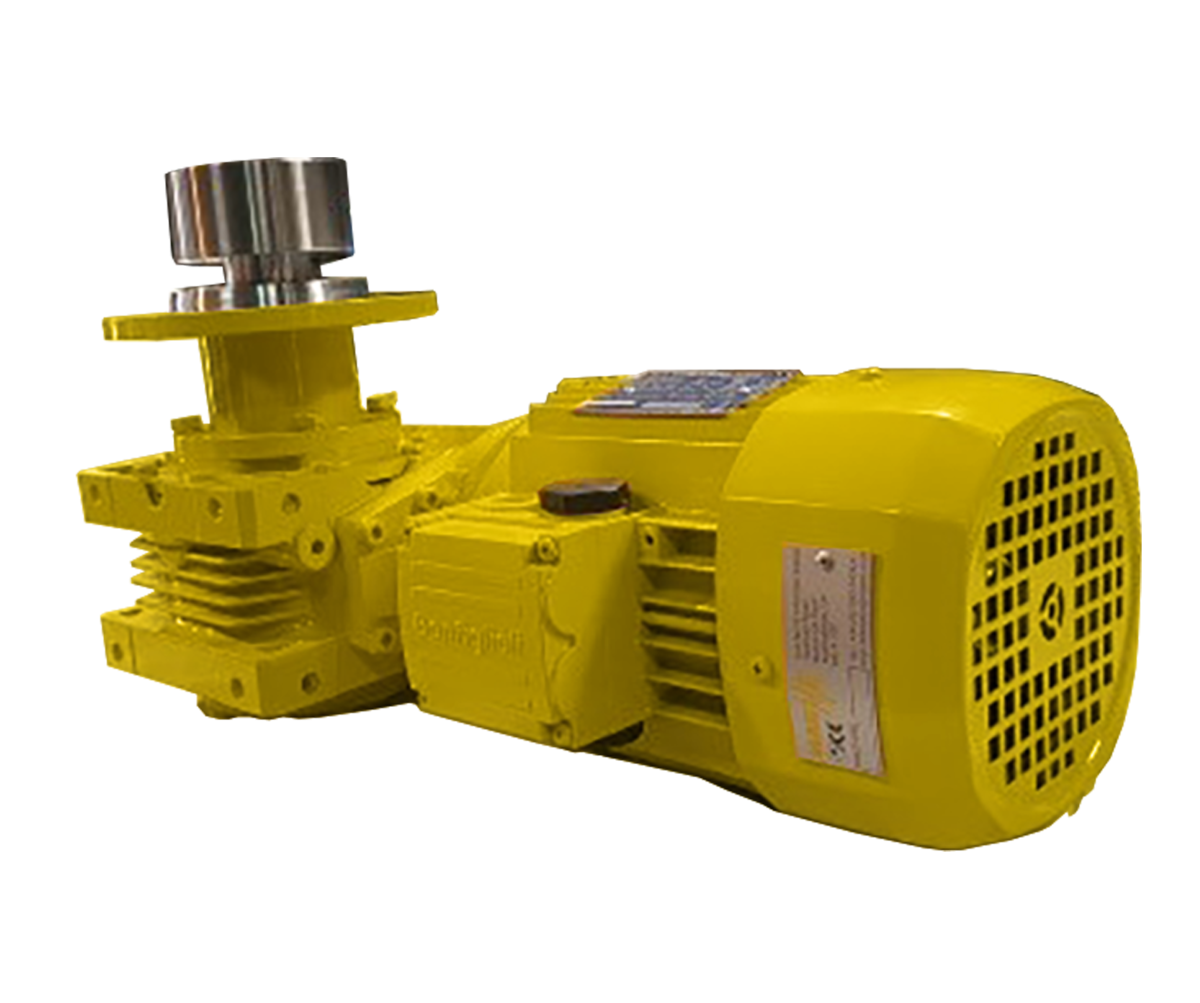

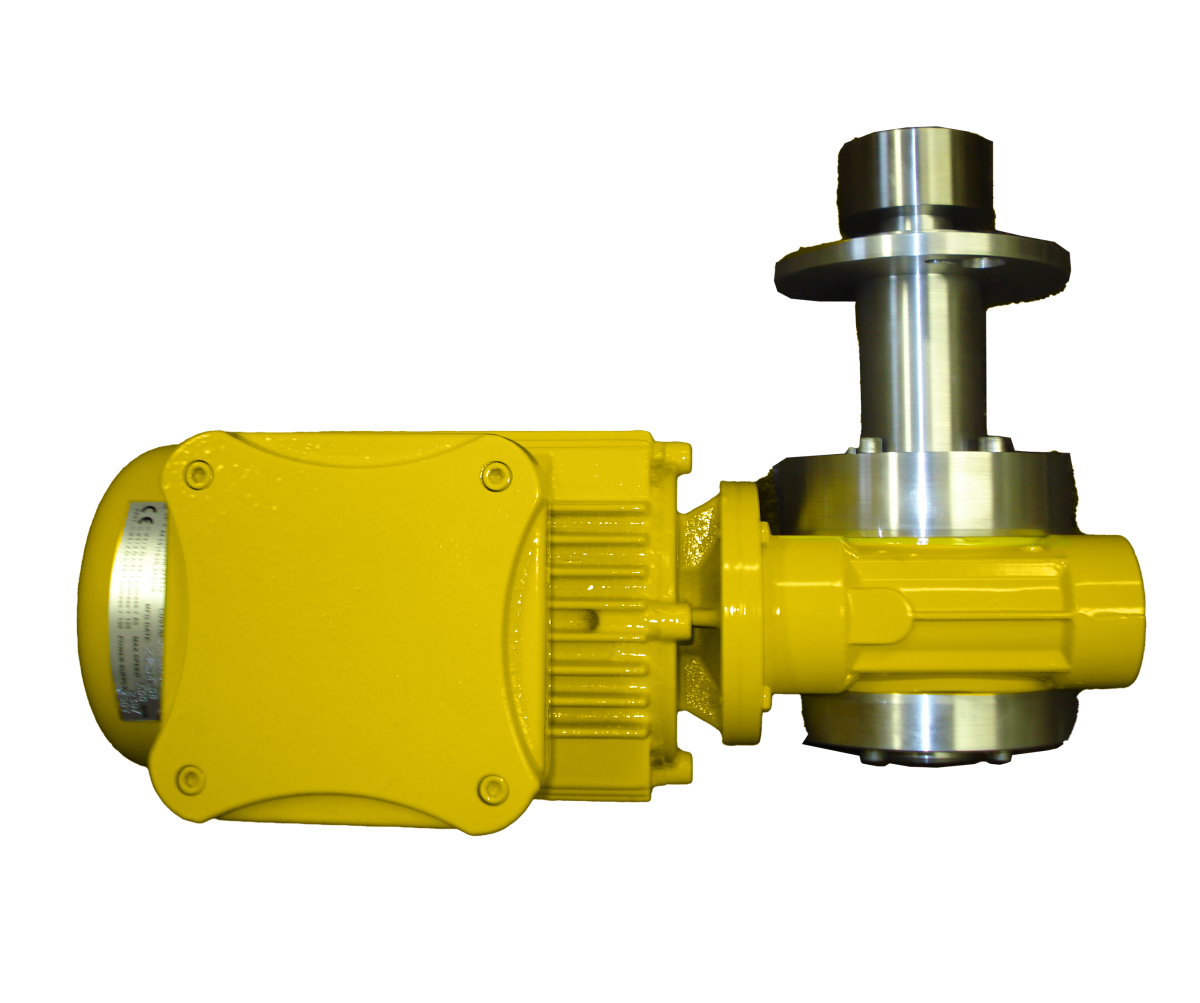

ATEX MIXER

For Mixing Capacity of 10 Litres up to 30,000 Litres. Used in Explosive or Fire Risk Environments. Available in both AC and Air Drive Unit Options.

JUST SOME OF THE BENEFITS OF THE MIXER.

No Mechanical Seal

The Magmix has its own bespoke welded in vessel pad , eliminating the need for complicated mechanical seals which are liable to leak and can lead to product contamination and other risks.

Transferable drive unit

If you have more than one of the same vessel and Mixer the Driveunits can be transferable to each vessel so can save on costs and also as the external drive unit is attached to the mixing vessel pad with a quick release tri-clamp or slide up clamp system to allow a quick changeover with minimum downtime.

MagMix can be supplied with a control unit

The Mixer can be supplied with a Stand alone control unit if required, which in turn gives a stepless variable speed facility, ensuring full control of mixing power during start-up, product blending and vessel draining with many options to suit our customers needs these are truly built to the customers required specification.

MagMix is a bottom drive design

Our MagMix Mixer is a pure bottom drive design which when fitted with a low volume mixing head, very low controlled blending can be achieved and all Internal surfaces can be cleaned and sterilised in place (CIP, SIP) using pressurised steam and without the need to remove any parts from the vessel.

Fully ATEX Compliant mixer

Fully ATEX Compliant Mixers and control Panels can be supplied as an option.

Mixer Compliance

Complies with all pharmaceutical, healthcare and food regulations.